The production of custom printed baseball hats is a complex and delicate process that requires multi-step coordination and cooperation. The following is a detailed production process:

- Design stage

(1)Requirement collection and analysis

(2)Material selection and procurement - Material selection and procurement

(3) Fabric selection

(4)Accessory procurement - Plate making and printing

(5)Plate making

(6)Printing - Cutting and sewing

(7)Fabric cutting

(8)Sewing - Quality inspection and packaging

(9)Quality inspection

(10)Packaging - Logistics and Delivery

(11)Logistics Arrangement

(12)After-sales Service

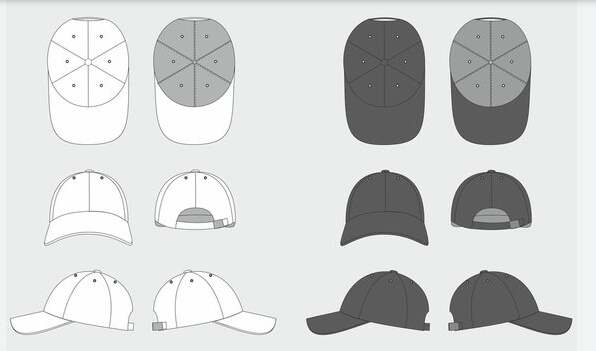

1. Design stage

(1)Requirement collection and analysis

Customers submit customized requirements, including color, size, material, pattern and other detailed information. The design team makes preliminary design ideas based on customer needs.

(2)Material selection and procurement

Designers draw sketches and communicate with customers several times until the final design is confirmed. The design sketch will include detailed size, pattern position and color matching.

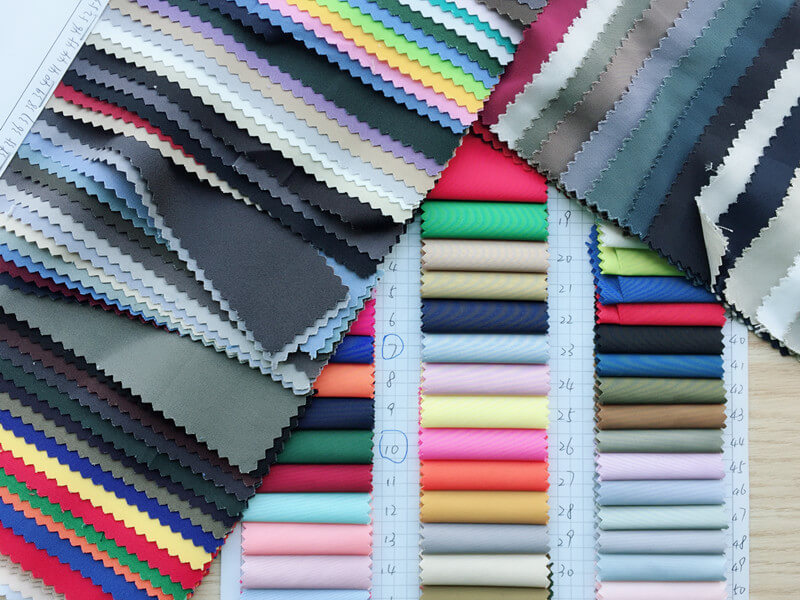

2. Material selection and procurement

(3) Fabric selection

Select suitable fabrics such as cotton, polyester, wool, etc. according to customer requirements. The quality of the fabric directly affects the comfort and durability of the hat.

(4)Accessory procurement

Purchase other accessories such as visors, hat bands, linings, etc. to ensure that all materials meet the design requirements and quality standards.

3. Plate making and printing

(5) Plate making

Plate making is carried out according to the design pattern. Plate making is the basis of printing, which affects the clarity of the final pattern and the accuracy of the color.

(6)Printing

The design pattern is printed on the fabric by silk-screen printing, heat transfer or embroidery. Each printing method has its advantages, and the choice depends on the complexity of the pattern and the needs of the customer.

4. Cutting and sewing

(7)Fabric cutting

According to the design drawings, use professional cutting equipment to cut the fabric into the various parts required for the hat, such as the crown, brim, etc.

(8)Sewing

Use a sewing machine to sew the cut parts into shape. This step requires the workers to be skilled to ensure that each hat meets the design and quality requirements.

5. Quality inspection and packaging

(9)Quality inspection

The finished baseball caps need to undergo strict quality inspection to ensure that there are no defects, no damage, clear patterns, and firm stitching. Problems found during the quality inspection process should be reworked and corrected in time.

(10)Packaging

The baseball caps that have passed the quality inspection will be ironed to ensure a smooth appearance. Then pack according to customer requirements, usually in plastic bags or cartons to prevent damage during transportation.

6. Logistics and Delivery

(11)Logistics Arrangement

Choose the appropriate logistics method according to the customer’s location, such as express, sea or air. Ensure that the goods can be delivered to the customer safely and on time.

(12)After-sales Service

After delivery, provide after-sales service, handle customer feedback in a timely manner, solve customer problems, and ensure customer satisfaction. Every link of the entire production process needs to be strictly controlled to produce high-quality custom printed baseball caps to meet customer needs. Through scientific management and meticulous operation, ensure that every baseball cap becomes a boutique in the minds of customers.